Design close

to the riders

- Fab Lab

- Add Lab

- Workshops

- Test room

- Rain Room

- Tank

Tribord Sailing Lab

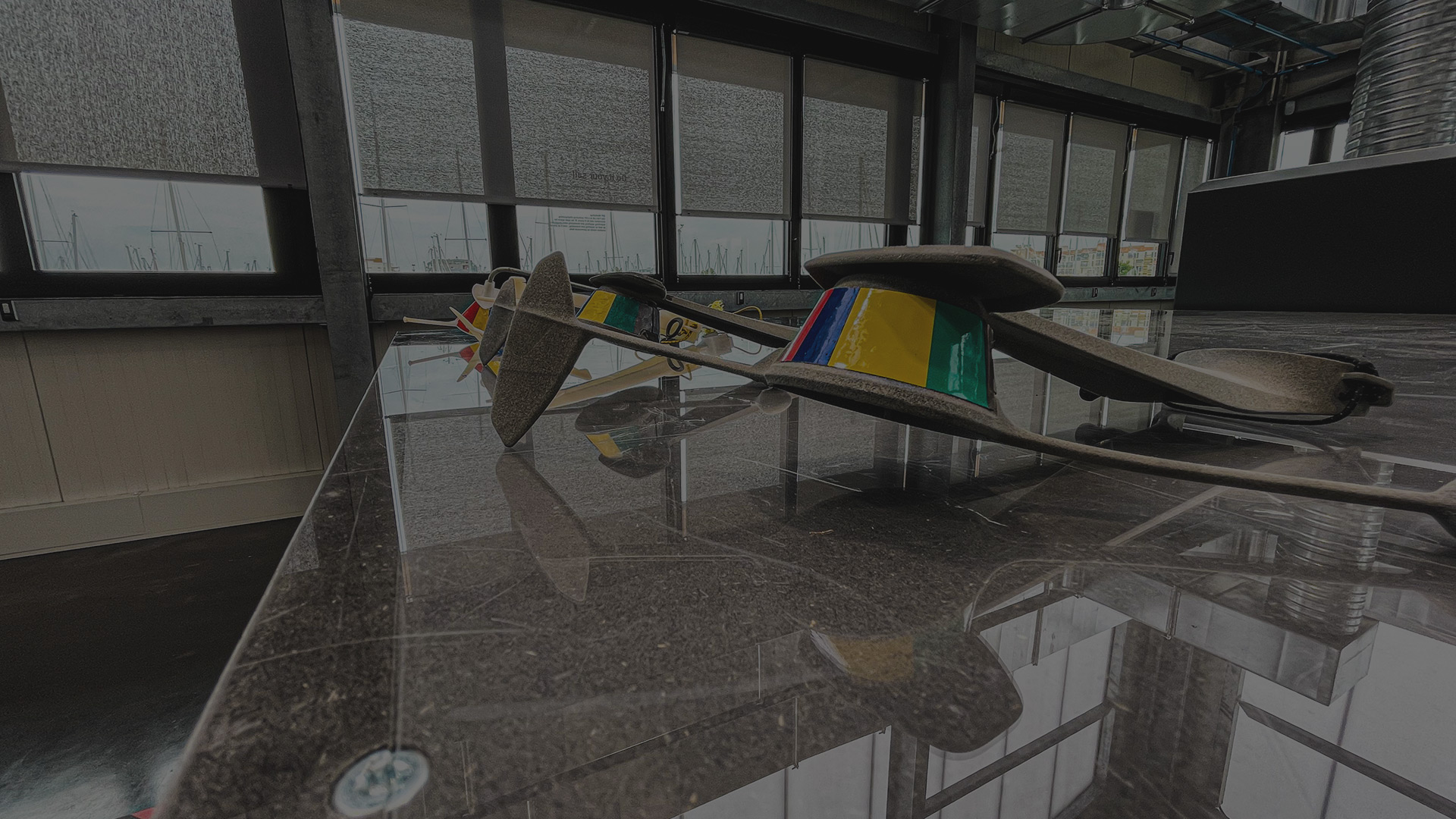

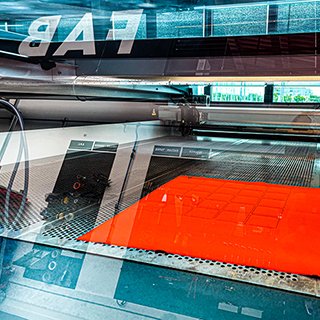

Fab Lab

This workshop has a "DO IT YOURSELF" / "QUICK AND DIRTY" credo. With its prototyping space to to bring ideas to life, it is an obligatory passage to validate the tests, where materials are cut, built and tested: a place where creativity is fully expressed.

The products that come out of the Fab Lab are not the most accomplished, it's the first step after the design, but these tests are essential to imagine the product in its final version. In this workshop, we come to prototype our ideas live without wasting time, and then test them at sea, and come back to prototype. So, thanks to these tools and machines, we can move fast and be agile, to offer ever more innovative and high-performance products.

Romain Laurant

Technical Director, Tribord

Tribord Sailing Lab

Add Lab

The ADD LAB meets a number of needs for our employees. From prototyping, to small series production, to an online catalog of parts and tools for the after-sales service, through to testing and co-development of materials and technologies.

They support our internal teams to produce, on request, a multitude of personalised and adapted sports products.

62 grams

That's the weight of a 3D printed dinghy weathercock on the Starboard 5S.

It takes about 5 hours to give it shape.

Tribord Sailing Lab

Workshops

This part of the workshop, which is dedicated to textiles, is equipped with a range of machines: a waterproofing machine to ensure that the products are waterproof, sewing machines, an ultrasonic welding machine, etc. The workshop is also equipped with an Alys plotter, which allows the prototype pattern to be printed in real size, transforming the drawings into a puzzle.

OFFSHORE 900 jacket

70% time saving in assembly 150 pieces 3 days of assembly Co-designed with experts

Tribord Sailing Lab

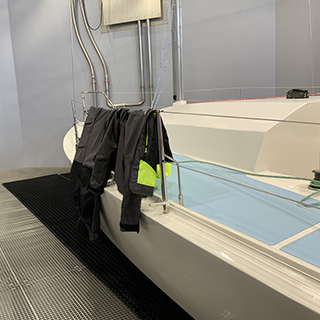

Rain Room

A unique room in the world, this room reproduces several types of bad weather: from a small drizzle to a tropical storm! Designed and imagined from A to Z by the team, the aim of this room is to reliably create conditions at sea and to test the behaviour of all the products in an almost real environment, by testing their waterproofing and adhesion.

Three years ago, I was given carte blanche to imagine a place to recreate conditions at sea.

After 3 years of reflection and supported by the expertise of our teams and partners, the Rain Room was born.

The objective: to have conditions that can be repeated to confirm our tests, before the big swim at sea!

Théo Joly

Engineer

Tribord Sailing Lab

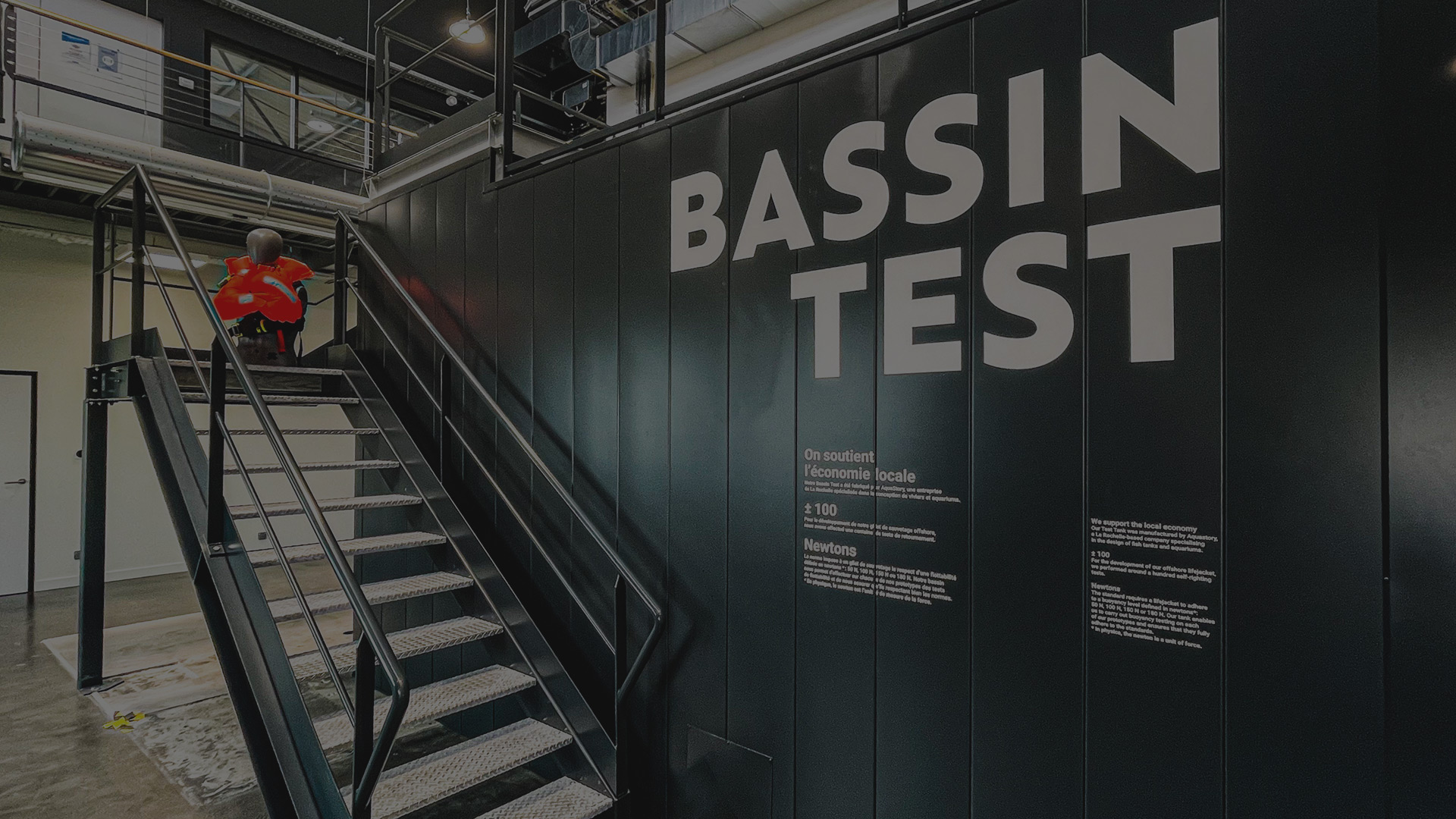

Tank

This tank, filled with 27m3 of water and three metres deep, allows easy testing of lifejackets that meet specific Personal Protective Equipment (PPE) standards. The waistcoat must turn over even if the person is unconscious, so that he or she can breathe. Dummies or real testers then jump into the water to check and validate the various parameters.